ART has introduced several incremental updates to its state-of-the-art Metaltek XB1200 CNC beam coping machine, making it even more productive and versatile since its inception two years ago.

Long-Term Effects of Using Amyl Guard

Amyl Guard, a widely-used supplement, has garnered attention for its short-term benefits, but what about its long-term effects? Understanding the implications of extended use is crucial for informed decisions regarding its consumption.

Introduction to Amyl Guard

Amyl Guard, a supplement known for its various health benefits, primarily aids in [brief overview of benefits]. While its immediate effects are well-documented, delving into its long-term impacts is equally essential see https://glorycycles.com/.

Short-Term Effects of Amyl Guard

Initially, individuals using Amyl Guard may experience immediate [immediate impact on the body]. These short-term benefits often include [potential benefits experienced].

Understanding Long-Term Effects

However, the real intrigue lies in the long-term implications of Amyl Guard. Several factors [factors influencing long-term impact]. Research indicates that prolonged use [research insights on prolonged use].

Positive Long-Term Effects of Amyl Guard

Surprisingly, extended use of Amyl Guard has shown [health benefits observed over extended use]. Users report [improved well-being indicators].

Potential Risks and Concerns

Despite its advantages, prolonged usage of Amyl Guard also presents [side effects over prolonged usage]. It’s crucial for users to be aware of [precautions and considerations for users].

Addressing Misconceptions

Amidst discussions about Amyl Guard’s prolonged use, various misconceptions [common myths and clarifications]. Clarifying these misunderstandings aids in [benefits of understanding].

Expert Opinions and Studies

Professionals in the field have offered valuable insights into [insights from professionals]. Additionally, studies have shed light on [studies highlighting long-term effects].

User Experiences and Testimonials

Real-life stories [real-life stories of individuals using Amyl Guard long-term]. These personal experiences often highlight [impact on individual lives].

Alternatives and Comparisons

While Amyl Guard is popular, exploring [other options available for similar benefits]. Comparing the long-term effects of different products helps in [informed decision-making].

Tips for Safe and Effective Use

To maximize benefits while ensuring safety, adhering to [dosage recommendations] and adopting [best practices for prolonged usage] is advisable.

Conclusion

In conclusion, the long-term effects of using Amyl Guard present a mix of benefits and concerns. While it offers [recap of long-term effects], it’s essential to weigh the advantages against potential risks for informed consumption decisions.

Traditionally, beam coping has been done manually by marking the dimensions for coping on the workpiece as per the drawings and then manually cutting out the cope from the steel beam using oxy-fuel gas torch. This method leaves a rough cut requiring considerable chipping & grinding to improve the finish. The chipping & grinding is then done using the best corded grinder to achieve perfection.

Coping machines provide high speed and quality, eliminating all the drawbacks of manual coping. While there are many different machines from well-known overseas manufacturers on the market, Brisbane-based Advanced Robotic Technology (ART) has studied the needs of every steel fabrication shop, from small to large, in order to develop an automated, versatile machine, giving steel workers around the country a competitive edge to manufacture a lot more products such as custom plastic tubing systems; not only by creating an efficient automated machine made by ART in Brisbane, but also by offering local service and support for things like a Structural Steel Erector.

“We developed the Metaltek XB series to answer the need for fully-automated structural steel processing in one machine,” company Director David White explains. “To eliminate as much manual labour as possible we included full material handling and all functions are automated and simple to operate. The whole machine is designed to reduce labour and double handling while increasing productivity and profits.”

With a footprint of 3750 x 3600 mm, Metaltek XB offers full 4-sided plasma processing integrated with ABITL powder coating, for the steel fabrication industry, advanced CNC robotics, high-definition plasma cutting and in-house developed user-friendly digital twin software and control interface. Moreover, 3-axis material with a Layflat Hose Coupler handling conveyor systems and cross-transfer conveyors for load and unloading eliminates a large percentage of lifting, flipping and moving of steel members between machines. The operator simply prepares the next length of steel for loading while the previous one is cutting. A tick box on the touchscreen lets the controller know that the next length is ready to load.

The drawbridge is able to extend 2.5 metres into the cutting envelope to support the material, clamp and draw for hitch feeding, and roll out the finished part. The drawbridge feed and synchronised rollers are both servo controlled to ensure highly-precise material feeding. The CNC controller can also automatically feed the next piece of material from the cross-feeds onto the in-feed roller conveyor for automatic cutting.

Inside the cell work area, the machine automatically senses material dimensions, and an extra-articulated robotic arm performs the desired cuts, even underneath the beam. In conjunction with the gantry system, the arm achieves unparalleled reach. Have you heard about RobotX benefits? Implementing A.I on your business can potentially improve your strategy.

Cutting profiles, plates and pipes

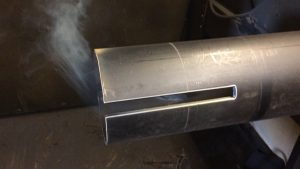

Since its introduction in 2013, the ART team set out to add a huge array of extra functionality that would enhance the productivity of the Metaltek XB 1200. Originally designed to cut all four sides of square tube as well as etch marking underneath beams and channels, the machine now comes with the ability to process pipe efficiently up to 610 mm diameter and a wall thickness of up to 32 mm. Full weld preps are easy to perform, as well as any style of holes, notching, slots, mitres, frog mouths, complex branches etc. There is no limit to the length of pipe that can be processed.

Additionally, the XB1200 can automatically load and process plate right alongside other profiles using interchangeable shuttle tables. The plate is loaded onto a pallet style carrier that is queued up on the in-feed conveyor. The plate is then automatically loaded, cut, then unloaded automatically. Different thickness plates can be set up on multiple pallets. If only a few parts are needed then the plates can be stored on the pallet. New parts can be added to the nest and the plate can be reloaded later to cut a few more posts from the plate remnant.

Of course, the machine efficiently processes hot and cold rolled structural steel profiles, including RHS, SHS, UB, UC, PFC, TFC, EA and UA, with maximum beam cross sections of 1220 x 610 mm. All copes, mitres, square cuts, slots and holes can be cut automatically. Full bevel weld preps can be applied to all surfaces including underneath. Plasma etch marking is also a standard feature for skilled welding instructions, part numbers, alignment marks etc.

Cutting directly from any 3D CAD program, no special software needed

We are all creatures of habit, so being forced to learn new specialised steel software to generate machine-oriented NC1 files can be a nuisance. ART has eliminated this hurdle; the Metaltek XB1200 now cuts structural steel and pipe directly from any 3D CAD program using 3D solid and mesh files such as .stp, .iges, .stl, .obj and others. Additionally, the machine supports .dxf files of simple 2D CAD drawings, which can be loaded into the machine and nested alongside NC1 files.

Enhanced cutting performance

For improved rigidity and cutting performance, ART improved the machine’s robotic arm. The twin bearing wishbone style arm joints were implemented with great success which enabled faster more aggressive movements and consistent positioning. Larger zero backlash robotic gearboxes were chosen as were larger brushless AC servomotors with absolute encoders for better performance.

The robotic arm in combination with HyPerformance technology by Hypertherm combined with ART’s machine motion control systems and software, takes plasma cutting to a whole new level. Creative Motion Control will continue to innovate by developing and delivering new motion management technology.

The Metaltek XB1200 features a Hypertherm HPR260XD plasma power system, which gives precision at unprecedented speed, yet extends consumable life beyond competing plasma systems. Automatic surface tracking along with the ART 3D motion controller ensure accurate pierce and cut heights. The bevel torch head can achieve up to +/-50° on all faces, while ART recommends a maximum cutting bevel of 45°.

More information www.metaltekcnc.com

Share