Used Machines.

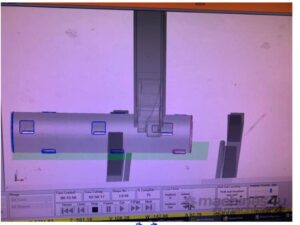

ART 1200 Metal Tek Plasma Beamline

Australian-Made ART Plasma Cutter with Hypertherm 260 Amp System – High Precision and Reliability

Designed and manufactured by Advanced Robotic Technology (ART) in Brisbane, this high-performance plasma cutter is engineered for precision and durability. Exclusively installed and maintained by ART, this machine has operated continuously since its commissioning, building a solid base of repeat clients and producing outstanding results.

Key Features:

Hypertherm 260 Amp Plasma Cutter: High-performance cutting for mild steel, aluminum, and stainless steel up to 36mm thick.

Robotic Arm Update: Upgraded in 2016 to include a modern robotic arm for enhanced flexibility and precision.

Camera-Assisted Material Measurement: Added in 2019 to accurately measure material location and size.

Extensive Cutting Capabilities: Can handle Universal Beams, Columns, Channels, Angles, SHS, RHS, and pipes, making it versatile for various projects.

Large Material Capacity: Capable of processing material up to 1200mm wide, 800mm high, and 18 meters long.

Advanced Software Compatibility: Reads NC, STL, and DXF files, along with 3D models for project-specific cutting and marking.

Additional Benefits:

Continuous Software Updates: Keeps the machine current with the latest advancements.

Available Support: Assistance via phone or online, in your time zone, for quick problem-solving.

Parts and Upgrades Readily Available: ART offers excellent support with parts and software updates for seamless operation.

Please call 0413 800 170 for further information.

ART 13200SX Profile Table.

Work area: 12500 x 2500mm

Spindle: 16HP 4 pole Air cooled

Tool holders 10 x HSK63 & Collets 10 x ER32

Cutting tools x 12 standard

Software: ToolShop

Safety Light Curtains – fore and aft

Swarf Guard/waste roller-seal pick-up X&Y

Swarf Extractor cyclone 2 drum with remote starter

ART Touch Screen Control Console

Laser Aligner/ digitizing

Contact

Primary – Tony Pal 0448 472 414

Secondary – Grant Kemp 0400 403 336