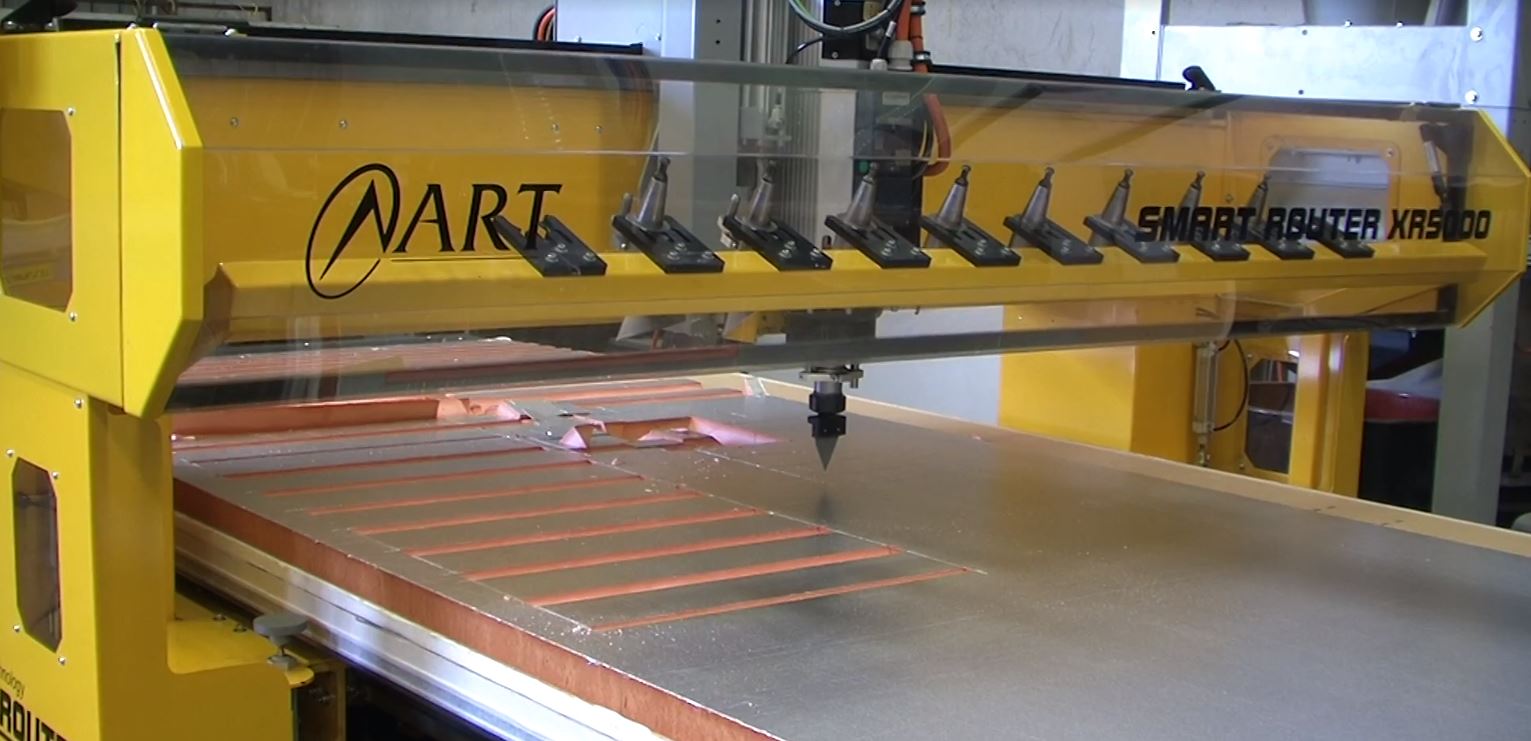

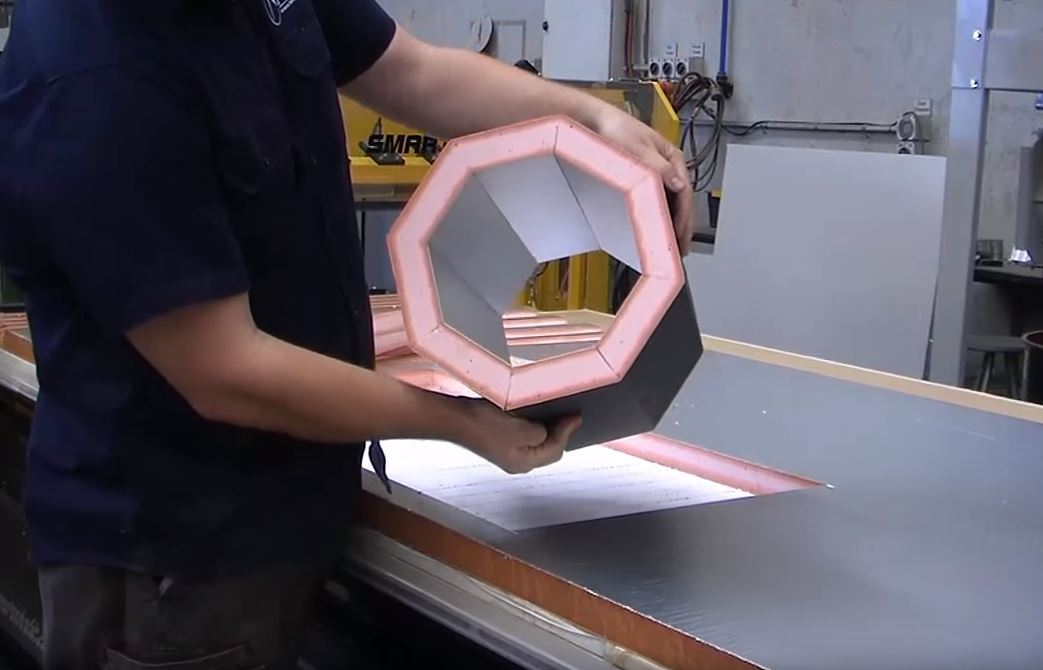

Description

For ducting and insulation manufacturing

The XRD Router is a custom spec machine with all the accessories needed to be the ultimate ductboard and insulation cutting machine. Based on the XR Router with added C axis and specialised tooling. Reciprocating saws, steered straight & bevel knives, pizza wheel cutters and more.