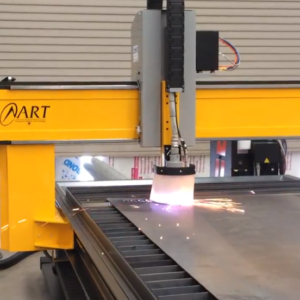

Description

High-definition Plasma cutting + Drilling + Tapping.

On one affordable machine

Traditionally plasma cutting tables have been divided into lower cost plasma only tables, or high cost cutting & drilling machines. The XRP Plasma/Drill machine was designed to fill a gap in the available machines. Now you can perform high definition cutting, drilling and tapping in light to medium duty materials.