ART stands behind every HSG Machine we sell!

Advanced Robotic Technology is the agent for HSG Laser around Australia. We are proud to be partnered with such a reputable company. When you buy fibre laser from ART you are getting the full support of our 25 years experience in cnc technology. We stake our reputation on it.

Rather than re-invent the wheel by trying to compete against world leaders in the fibre laser industry, ART have decided it was best to team up with the best and combine our resources to provide an excellent customer experience that cannot be provided by other importers. ART has a team of dedicated technicians that work in conjunction with HSG engineers in other countries to give the end user experience that has been lacking in the industry until now.

ART is an expert in automation and can assist with your every laser requirement, from basic light sheet cutting at 3kW, all the way up to 60mm plate cutting with 40kW or greater as they become available.

Our technically capable staff are more than salespersons… they are dedicated professionals that really know the cutting industry and work with you to achieve your desired outcome.

Technical Data

| Technical Data | ||

| Cutting Size | mm | 3048mm x 1525mm |

| Max Acceleration | G | 1.5 |

| Max Speed | m/min | 120 |

| Positioning Accuracy | mm/m | ±0.03 |

| Repeat Positioning Accuracy | mm | ±0.03 |

| Loading Weight | kg | 2500 |

| Voltage | V | 415V |

| Frequency | Hz | 50 HZ |

| Dimension | mm | About 4800×3600×2800mm |

| Power Requirement Data | KW/A | 42.5KW/85A(3000W) |

| Operation Requirement | |

| Electricity

Voltage: 415V Frequency: 50Hz Voltage stability: ±5% Voltage regulation: <2% |

Assist gas Supply Cutting

Purified dry compressed air and high purity,Discharge Oil Content :≤0.01ppm.Solid≤0.01um .Dew point:-20℃ ~ -40℃ Oxygen (O2) and nitrogen (N2) purity not less than 99.9% Air ,Oxygen and nitrogen pressure not less than 16 bar

|

| Sheet metal

Homogeneous Smooth Clean |

Compressed Air Supply Device

Pressure: 8 bar Volume: 0.6m ³ Discharge Oil Content :≤0.01ppm.Solid≤0.01um . Dew point:-20℃ ~ -40℃ |

Configuration

|

|

Laser Source – Raycus or IPG

The most well-known brands of laser resonator in the market. High output power, high quality laser beam, over 40% coefficient of efficiency. Compact design, solid and easy to install. high electrical efficiency and environmental friendly. HSG global strategic partner |

|

Laser Head – HSG Self Developed (6KW)

Focusing Accuracy up to 0.01mm With close-loop motor installed inside the laser head, the focus speed is much faster than market level to achieve higher piercing speed in high thickness materials. Full Protection Inside & Outside Equipped with double bottom protective lens inside, extending the lifetime of main lens. Equipped with stainless steel cover outside, protect the lines from laser flares. |

|

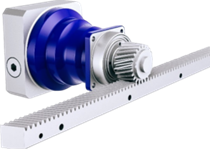

Speed Reducer & Gears

Backlash of less than 4 arc min. Smooth operation, high transmission accuracy and good feed force. The reduction gear and wheel gear are welded to effectively guarantee the accuracy of the machine tool. |

|

|

Control System – HSG Alpha T

Bus control through EtherCAT protocol, fast control speed with HSG fiber laser cutting optical and transmission system. Equipped with multiple function like scan cutting, 5 stage piercing, laser energy precise control, maintenance reminder, process report etc. |

|

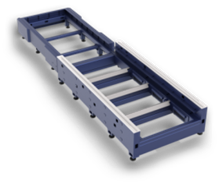

Machine Body – Semi Hollow Welding Structure

Extra-high Strength Steel Tensile strength over 500 MPa Strong Rear Frame Added taper pin lock, 0 shaking during cutting and loading process. Strong blade worktable, bigger holding capacity. Professional Manufacture Process Each machine body will pass at least 6 steps including welding process,stress annealing , rough machining etc. for release the welding stress. |

|

Crossbeam – Aluminum Beam

Light-weight, and with good dynamic performance, with better flexibility and ductility. Without heavy weighted iron beam, no need to operate beam with large inertial motor power. Less electricity is consumed during running. |

Cutting Capacity

| Material | Thickness | ||

| (m/min) | |||

| Carbon Steel (O2) | 1 | 7.0-12.0 | |

| 2 | 5.0-6.5 | ||

| 3 | 3.5-4.0 | ||

| 4 | 3.0-4.0 | ||

| 5 | 2.5-3.0 | ||

| 6 | 2.6-3.2 | ||

| 8 | 1.5-2.6 | ||

| 10 | 1.2-1.5 | ||

| 12 | 1.0-1.5 | ||

| 16 | 0.5-0.7 | ||

| 20 | 0.2-0.4 | ||

| 22 | |||

| 25 | |||

| Stainless Steel (N2) | 1 | 42.0-62.0 | |

| 2 | 12.0-25.0 | ||

| 3 | 7.0-12.0 | ||

| 4 | 4.0-6.5 | ||

| 5 | 2.5-4.5 | ||

| 6 | 1.5-3.2 | ||

| 8 | 0.6-1.0 | ||

| 10 | 0.4-0.8 | ||

| 12 | |||

| 14 | |||

| 16 | |||

| 20 | |||

| Aluminum

(N2) |

1 | 35.0-55.0 | |

| 2 | 12.0-20.0 | ||

| 3 | 7.0-10.0 | ||

| 4 | 3.7-5.0 | ||

| 5 | 2.5-3.5 | ||

| 6 | |||

| 8 | |||

| 10 | |||

| Brass

(N2) |

1 | 28.0-55.0 | |

| 2 | 9.0-20.0 | ||

| 3 | 4.5-10.0 | ||

| 4 | 2.5-4.5 | ||

| 5 | 1.2-2.5 | ||

| 6 | |||

| 8 | |||

| Copper

(O2) |

1 | 25.0-38.0 | |

| 2 | 6.5-9.0 | ||

| 3 | 1.7-3.8 | ||

| 4 | |||

| 5 | |||

| 6 |