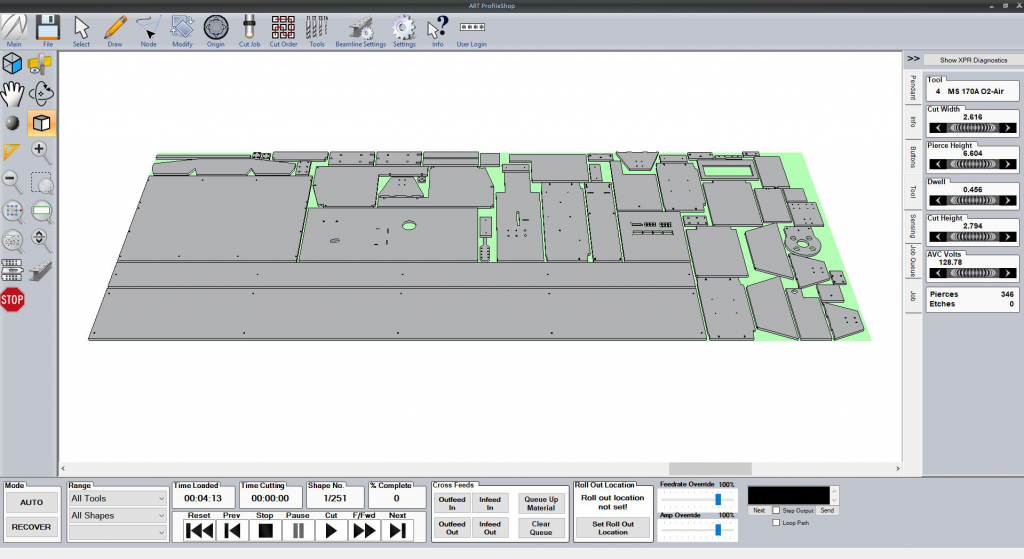

CNC machine controller interface that does so much more

ART ProfileShop 4 is one single software package that controls all manner of cnc machines from ART. It is a windows based touch screen enabled graphical interface that does so much more than your average machine controller. It works in conjunction with a range of dedicated motion controllers boards that can handle up to 16 axes. It also supports all manner of automatic tool changers including Rack, Rotary, Pop-up and Fixed tool changers. It also supports bevel cutting, aggregate tooling, and custom kinematics for complex devices such as robotic arms etc.

ART ProfileShop 4 is one single software package that controls all manner of cnc machines from ART. It is a windows based touch screen enabled graphical interface that does so much more than your average machine controller. It works in conjunction with a range of dedicated motion controllers boards that can handle up to 16 axes. It also supports all manner of automatic tool changers including Rack, Rotary, Pop-up and Fixed tool changers. It also supports bevel cutting, aggregate tooling, and custom kinematics for complex devices such as robotic arms etc.

ProfileShop incorporates a machine vision module that can identify and modify cut paths to suit stretched print and cut jobs for signwriters, screen printers etc.

DXF Import and full automatic toolpathing!

ProfileShop 4 has the ability to import parts or complete nests as a DXF file direct from your CAD program. This requires no toolpath generation or G-code export.

DXF import is especially useful for plasma cutting machines as it optimally selects the appropriate tool path parameters including High Definition or True Hole strategies to suit the individual shapes. ProfileShop will then reposition lead-ins and optimise cut order to reduce part movement and processing time. Layers can also be assigned to use specific tools such as drills or taps.

The DXF Auto Toolpath option is extremely time efficient and ideal for straight forward production cutting. No special software is required other than a standard 2D cad software package such as Autocad, DraftSight or TurboCAD

Automatic Nesting & Cut Order

Aimed at simpler jobs such as plasma cutting which have one or two processes, such as marking and cutting for example.

The Automatic Nesting feature is a recent development that enables any number of parts files (DXF, NC1, CNC) to be imported directly into the controller.

Quantities for each part can then be specified. Automatic quantities can be read from NC1 and correctly formatted DXF files.

Parts are then separated into their correct materials (also specified in the files) and nested quickly and efficiently across multiple sheets and thicknesses.

Appropriate cut order and start point locations are then applied for efficient cutting and reducing possibility of movement during cutting.

G-Code Import

G-Code (NC file) import is native and supportsmost standard post processors.

ProfileShop is tool aware. ProfileShop contains extensive databases describing all available tooling. This means that it contains all parameters to operate all tools that it supports and can run the simplest of NC code files while taking over all tool operations automatically. Of course, ToolShop 4 can obey normal M and G codes if your post processor supports all of the advanced functionality available in ProfileShop 4

Some available tooling includes: –

- Drilling only requires the Tool Number and a vertical line in the NC code. All RPM, Feed-rate, Lube, Pecking, Retraction are calculated automatically by Profileshop

- Example code:

T36 (8.8mm Drill)

G0X1000Y1000

G0Z5

G1Z-10F1200 (1200RPM – optional)

G0Z5

- Example code:

- Tapping only requires the Tool Number and a vertical line in the NC code. All RPM, Thread Pitch, Feed-rate, Lube, Pecking, Retraction etc. are calculated automatically by Profileshop

- Example code:

T56 (M10 Tap)

G0X1000Y1000

G0Z5

G1Z-10F1200 (1200RPM – optional)

G0Z5

- Example code:

- Routing only requires the Tool Number and the pre-kerfed tool path in the NC code. All RPM, Feed-rate, Lube, etc. can be calculated by Profileshop

- Example code:

T8 (6mm Router Bit)

S18000 (Optional Spindle RPM)

G0X40Y100

G0Z5

G1X50Y100Z-10F500

G1X200Y100F4000

G03X200Y200I200Y150F4000

G1X40

G1Y100

G1X50

G0Z5

- Example code:

- Knife cutting only requires the Tool Number and the cut path. All tangential C axis commands, bevel knife insertion and retraction, lifting at corners, feed-rate etc. are calculated automatically by ProfileShop

- Example code:

T16 (45 Degree Knife Tool)

G0X40Y100

G0Z5

G1X50Y100Z-10F500

G1X200Y100F4000

G03X200Y200I200Y150F4000

G1X40

G1Y100

G1X50

G0Z5

- Example code:

- Tangential Saw Cutting only requires the Tool Number and the cut path. All feed-rates, RPM, C axis commands and insertion angles (for angled saw) and lifting at corners are calculated by ProfileShop. Saw will automatically lift and turn at corners.

- Example code:

T22 (Aggregate saw tool)

S5000 (Optional RPM)

G0X100Y100

G0Z5

G1Z-10F500

G1X200F8000

G1Y200

G1X100

G1Y100

G0Z5

- Example code:

- Aggregate tooling is supported as 4 or 5 axis for side drilling, angled milling, 5 axis machining. Supports simultaneous X,Y,Z,A,C axis co-ordinates in nc code. Programming coordinates are usually specified as tip centre position.

- Example code:

T7 (5 Axis Head)

S24000

G0X100Y80Z10A45C90

G1Y100Z-10F1000

G1X200F4000

G3X200Y200Z-10I200J150A45C270F4000

G1X100

G1C0

G1Y100

G1C90

G1Y80Z10F18000

G0Z5

- Example code:

- Rotary B Axis is supported for cylindrical machining in a chuck style application. Supports simultaneous X,Y,Z,B axis coordinates in nc code. Can be used in conjunction with 5 axis head.

- Example code:

T8

S18000

G0X0B0Z10B0

G1Z-1F1000

G1Z-25B180F5000

G1Y200Z-10B90

G0Z5

- Example code:

- Plasma Cutting only requires the Tool Number, Material Type and Thickness in header, and the pre-kerfed cut path. All feed-rates, gas types, pierce height, cut height, arc voltage etc. are calculated automatically by ProfileShop

- Example code:

(MATERIAL=Mild Steel)

(GAUGE=6)

(SHEET LENGTH X WIDTH=2400 X 1200)

T6

D5.3 (pre-kerfed width – used for automatic Tru Hole conversion)

G00X50.00Y50.00

G00Z1.

G01Z0.00

G01X75.18Y75.68

G03X78.13Y74.45I78.13J78.63

G03X82.3Y78.63I78.13J78.63

G03X81.08Y81.58I78.13J78.63

G00Z5

- Example code:

- Laser Cutting only requires the Tool Number, Material Type and Thickness and the cut path. All gas pressures, feed-rates, pierce height, cut height, auto focus, wattage, PWM and more are calculated automatically by ProfileShop

- As per Plasma Cutting above

- Water-jet Cutting only requires the Tool Number, Material Type and Thickness, and the cut path. All feed-rates, pump pressures, cut height etc. are automatically calculated by ProfileShop

- As per Plasma Cutting above

- Tangential Inkjet Print-head only requires the Tool Number and the Text to print. Also supports multiple line style printing for cut lines, fold lines, arrows, assembly instructions etc. Generates printing along curves or any angled path. Controls print-head rotation automatically. Different width characters also supported. Support for Rea-jet, Matthews and Domino printers

- Example code:

T80 (Select Printhead)

M101(This is the text to be printed)

G0X100,Y100 (Rapid to start of text)

G0Z10 (printhead height above material)

G1Y300F15000 (Baseline of text or marking)

G0Z20 (Retract)

- Example code:

- Laser Digitising is provided for tracing existing patterns or parts. The operator can manually jog the laser over points or arcs and generate an extremely accurate representation of the shapes. Arcs only require end points and a single point along the curve. Continuous curves can easily be plotted.

- Surface Mapping is supported. Simply specify the X,Y,Z Minimum and Maximum coordinates, and the resolution. the machine will automatically and efficiently probe the surface to generate a cloud point file for importing into your modelling software.

- Probing can be used to locate origin of plate, align plate rotation by one edge, find centre of hole etc.

Some other awesome features: –

- Start/Stop is automatic. The tool will automatically retract after a stop is activated. Pressing Start simply picks up where it left off. Angled bevel knives will retract at the angle of the knife. Taps will unwind automatically when lifting. Aggregate T slot type tools will even retract along the path before lifting.

- Emergency stops are handled with ease. The machine will stop immediately when an E/stop is activated. After resetting the E/stop the machine will then retract to a safe height. Pressing cut again resumes exactly where it left off. Retraction rules for all tools are obeyed.

- Recovering a job half way through is simple. Start at any shape, start at any point along a path, locate the nearest point to the tool and start there. A marker shows on the screen exactly where it will recover when start is pressed.

- All accessories can be controlled through M-codes, but are generally handled automatically. ProfileShop knows the accessory defaults for each tools/material combination and will control vacuum pumps, lubrication nozzles, dust & fume extractors, vacuum hold down sectors as required be each tool.

- Automatic Sheet Loading is supported. ProfileShop controls vacuum cups, pop-up locating pins, conveyors etc. as required

- Vacuum Valves are automated by ProfileShop. It calculated where material is located on the deck of a cnc router and turns the various zones on or off as required. Manual override is provided.

- Dross/Swarf conveyors are automatically turned on when cutting and off after a period of inactivity.

- Automatic File Loading is supported to efficiently work through a batch of nests. Just load the files into a batch folder, tick the Auto Load Next File button and it will cycle through each job automatically.

- Automatic Work-cell Cycling enables the operator to set up automatic cycling between 2 or more work cells. Once a job finishes naturally (without interruption) the machine will cycle to the next fixture location.

- Multiple NC Import Settings means that different file types can have different import settings. some can be absolute, incremental, inch, metric etc. Some can support all file parameters such as feed-rate, RPM etc. while others use the automatically calculated parameters. All parameters not supplied automatically fall back to the defaults for that tool/material combination.

- Wireless Pendant Support enables the operator to get close to the action for setting up jobs, or to monitor machine progress from further away. Safety function locks out Touchscreen operation when pendant in operation. Precise jogging by pendant handwheel allows adjustments down to 0.01mm resolution.

ART ProfileShop 4 can automatically control all of the following options...

This is a highly technical product that requires setup by experienced technicians to support various machine configurations.

If you have an application that you feel would suit ART ProfileShop then please contact us via the contact form below.