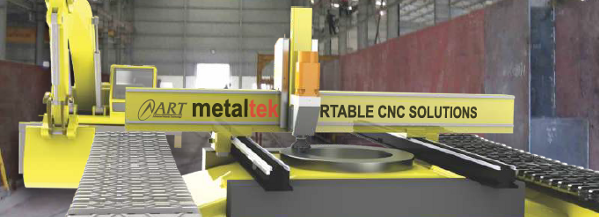

metaltek by ART

Modular multi-function CNC machining system

ART brings you the metaltek modular multi-function cnc manufacturing and machining system. This new breed of machine is fully portable and is able to provide an unparalleled range of machining functions in the field and workshop.

ART brings you the metaltek modular multi-function cnc manufacturing and machining system. This new breed of machine is fully portable and is able to provide an unparalleled range of machining functions in the field and workshop.

It can operate as a can seamer, as well as processes like face milling, drilling, pocketing, beveling, thread milling, tapping, plasma and oxy profiling as well as surface mapping (probing) and reverse engineering through digitizing are all available with this product range.

Why a portable solution?

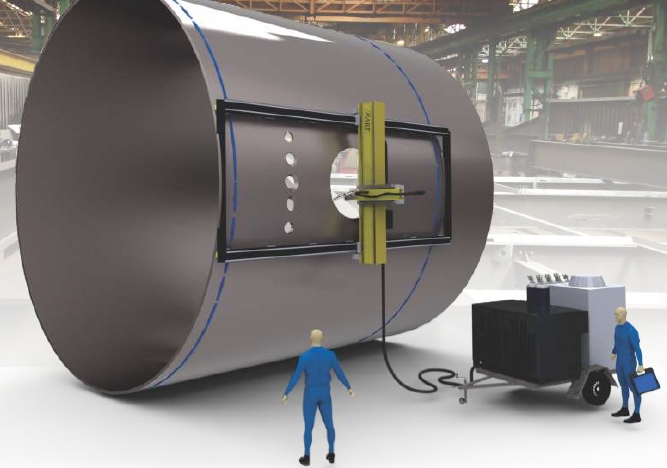

Repairs often create “double jeopardy” for mining, oil&gas companies as emergency fixes have high costs while the asset is simultaneously down and not producing revenue. Downtime, and the clock is ticking. As a result, it is important to have the right equipment at hand and onsite if a piece of critical mining equipment, which cannot be moved to the shop, is broken.

Some workpieces are simply too heavy to be transported to the machine or even too large to be machined on a conventional CNC machine. As a result, the machine has to be transported to the workpiece, which is a very common scenario in industries working with large machinery, such as the mining or oil & gas industries.

Download multi-function machine brochure

Portable CNC weld preparation machine

ART brings you the metaltek portable 5-axis CNC weld preparation machine. This new breed of machine is fully portable and is able to process both curved and flat surfaces. The latest advancements in portable CNC plasma profile cutting gives you faster feeds, higher acceleration and advanced motion control algorithms.

Innovative cncnow 5 axis technology provides the ultimate weld preparation profiling machine. Combined with Hypertherm Hyperformance HPR800xd cutting system results in the highest quality plasma profiling available.

Download weld preparation machine brochure

Read more: Onsite weld preparation for maximum equipment uptime

Advantages at a glance:

- Recondition equipment on-site

- Reduce transport costs

- Minimise downtime

- Save time and money

Applications:

Draglines:

- Cutting out winch floors etc.

- Machining mounting points

- Re-surfacing slewing bearings

Excavators:

- Re-machine repaired track frames

- Re-surfacing slewing bearings

- Gearbox mounting surfaces

Pipelines:

- Pipe cutting

- Hips and mitres

- Weld preparations

Pressure vessels:

- Nozzle cutouts

- Man-way openings

- General weld prep

And many other applications…

Features & Capabilities:

- Horizontal, vertical and inverted operation possible!

- Easy to learn touchscreen controller

- Ruggedised for durability

- Supports industry standard CAD software (Autocad, Inventor, Solidworks etc.)

- Modular design allows for multiple configurations and features

- Sizes up to 10 metres in length

- Easy to transport

- Gantry or cantilever configurations possible

- Milling

- Surfacing

- Drilling

- Rigid tapping

- Thread milling

- Plasma cutting (air and high definition)

- Oxy fuel cutting

- Digitising & scanning (reverse engineering)

About us

Over the last decade, ART has introduced a range of world-beating developments for the CNC cutting industry, which are integrated in this new line of machines. Milling heads, plasma cutting torches, oxy fuel torches, auto sensing drill tools and rigid tapping are just a few of the developments that increase productivity and performance. ART’s ProfileShop V3 touchscreen controller combines ease of use with advanced features to automate all cutting settings, resulting in optimum cut quality. Our new wireless pendant allows for monitoring of the machine from anywhere in the factory. At ART, we are driven to do better every day.

Contact us for more information:

Email or phone 07 3393 6555

Visit our homepage to find out more about ART and our range of products, including CNC Plasma Cutters and Routers.