Insulated panels, Truck & Camper Bodies.

Australian manufacturer so busy they have to close the doors!

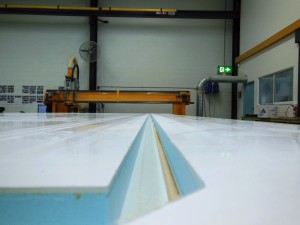

After installing a CNC router back in 2013 it has revolutionised the way we do business and allowed us not only to produce a composite panel faster, but also deliver a panel of unquestionable cut quality. The exceptional quality is something that could never have been achieved by our old hand cut method and we believe this is one of the many reasons our panels are becoming so popular.

The recent growth of StyroMAX and its related products has been somewhat amazing, so much so, earlier this month we decided to close our second business to allow StyroMAX to expand with some much needed factory space!

The current CNC router actually carries out two processes in the manufacture of our sandwich panel. First being the routing of the Styrofoam for panel inserts and the second obviously being the final cut once the panel has been laminated!

This has presented a problem we have never had; when the CNC is routing Styrofoam, it of course, is unable to cut sandwich panel at the same time. With our increasing production requirements, this creates production flow issues. This is an unacceptable issue for us and as such, we believe we are now in the market for a second CNC router. We would like to begin some discussions with you on the procurement of a second ART machine.