Aluminium Fabrication.

Fibreglass manufacturer expands into aluminium processing

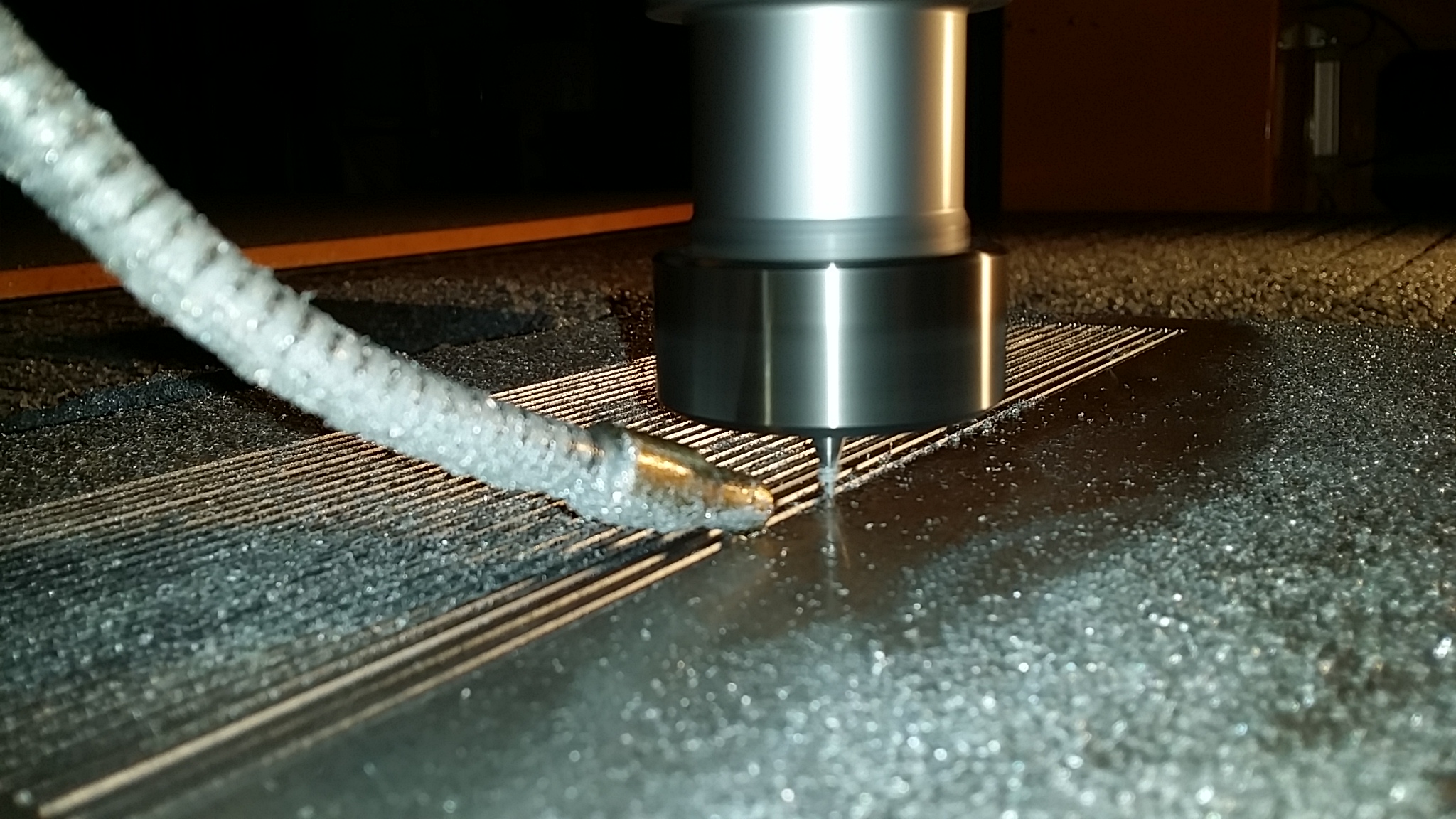

S&S Fibreglass can point to the purchase of their ART router as the beginning of a period of growth in business that saw them expand from fibreglass products into aluminium products as well. Today the Queensland-based companies S&S Fibreglass and ProCut keep the 4 m x 2 m XR5000 router fully employed manufacturing and prototyping for clients across Australia.

S&S Fibreglass can point to the purchase of their ART router as the beginning of a period of growth in business that saw them expand from fibreglass products into aluminium products as well. Today the Queensland-based companies S&S Fibreglass and ProCut keep the 4 m x 2 m XR5000 router fully employed manufacturing and prototyping for clients across Australia.

Austal Ships realise cost savings in the manufacture of aluminium ships

Austal, Palmer Johnson and Incat are just a few among aluminium ship builders who use automated aluminium routers which have been specifically designed for processing aluminium sheet and plate, on process areas up to 20 meters in length by one of the world’s most advanced manufacturer of CNC routers and plasma cutters, Advanced Robotic Technology (ART).

Austal, Palmer Johnson and Incat are just a few among aluminium ship builders who use automated aluminium routers which have been specifically designed for processing aluminium sheet and plate, on process areas up to 20 meters in length by one of the world’s most advanced manufacturer of CNC routers and plasma cutters, Advanced Robotic Technology (ART).

Boat builder brings it's aluminium cutting in-house

Aluminium Dynamics’ decision to bring all its aluminium cutting in-house with the purchase of two Australian-made CNC routers has resulted in improved component quality and efficiency.

Aluminium Dynamics’ decision to bring all its aluminium cutting in-house with the purchase of two Australian-made CNC routers has resulted in improved component quality and efficiency.

Aluminium Dynamics’ Director Grant Kemp in front of the company’s ART 9-metre cnc routers, specifically designed for the boat- and shipbuilding industry which typically processes a huge amount of aluminium sheets and plates.

Australia's largest bus manufacturer invests in locallv-built CNC routers

A high demand for its products and eager plans to drastically reduce lead-times led Australia’s largest bus manufacturer – Volgren – to invest in two Australian-built CNC router from Brisbane-based Advanced Robotic Technology (ART). The routers are being used to pre-drill the holes to further decrease lead-times and has proved to be cutting at four times the speed as the previous one.

A high demand for its products and eager plans to drastically reduce lead-times led Australia’s largest bus manufacturer – Volgren – to invest in two Australian-built CNC router from Brisbane-based Advanced Robotic Technology (ART). The routers are being used to pre-drill the holes to further decrease lead-times and has proved to be cutting at four times the speed as the previous one.